Time Sert Supplier Australia & New Zealand

Shipping to Adelaide South Australia, Brisbane Queensland, Melbourne Victoria,

Northern Territory, Perth WA, Sydney NSW, Tasmania direct shipping from comprehensive stock.

Full range of metric & inch Time-Sert sizes including

LS engine & Gen 3, M11x1.5 metric Time-Sert 1115 for Toyota engine – Honda engine, BMW engine, Ford engine, VW, Harley Davidson, Detroit diesel head bolt & sump thread repair kits.

Time-Serts are called “thread inserts” and are thin walled threaded sleeves generally made of steel. They have a screw thread on the inside and also on the outside and the “peak” or hill of the inside thread nests into the peak of the outside thread. This is how Time-Sert succeed in making the wall of their inserts extra thin.

Time-Serts are used for repairing stripped threads or in manufacturing to create stronger new threads in soft materials like aluminium or plastics. Because Time-Serts are so thin walled they take only a minimum amount of material around any hole needing to be repaired or inserted.

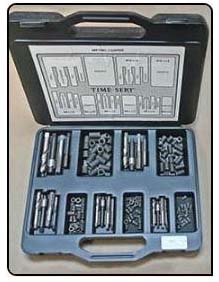

You will need a special set of tools for each size of Time-Sert you want to use. You can buy all the tools you need with a starter supply of Time-Serts in a ready made kit (pictured at left).

Usually the kit contains (1) a drill (of the correct size to drill out the hole to be repaired or strengthened) – (2) a special tap to retap the hole to the right size for the Time-Sert – (3) a “counterbore” to cut a recessed lip which takes the flange of the Time-Sert – (4) an “insert driver” to screw the Time-Sert in and lock it in place and (5) a starter supply of Time-Serts (usually a quantity of 5).

How does a Time-Sert work?

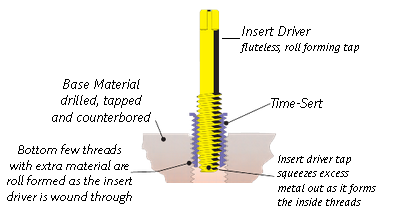

First of all, to explain how Time-Serts work, you need to know that a Time-Sert has extra metal left in the bottom internal threads when it is made. This means the bottom inside threads are not fully formed. (You can see this inside the black ring in the picture at left).

The yellow tool pictured at left is the Time-Sert driver tool. It is a fluteless, roll forming tap. As it is screwed through the Time-Sert it roll forms the bottom internal threads that had extra metal left in them during manufacture. This locks the Time-Sert into the “Base Material” by forcing the extra metal in these threads outwards.

Watch Video how a time-sert works & how you install one

How do I use the tools to fit a Time-Sert?

- Drill with the drill supplied in the kit.

- Counterbore the hole with the tool supplied. This makes a recessed lip

in the base material for the flange of the Time-Sert. - Tap the hole with the special size tap supplied in the kit.

- Screw the insert in with the insert driver supplied until you have gone

right through the insert and rolled formed the inside bottom threads. - The Time-Sert will now be in place seated below the surface in the lip

you made with the counterbore tool.

You can also get Time-Serts in boxed ranges of tools and inserts

Time-Sert produces convenient boxed kits containing a ranges of thread sizes as follows:

Metric Coarse Thread and Metric Fine Thread ranges.

Imperial (inch) Fine Thread and coarse thread ranges

For size listings and further information on the full Time-Sert range click here

Your Remedy if You Need to go Bigger or You Have to Fix a Stripped Helicoil or Time-Sert

Big-Serts – your second chance at thread repair.

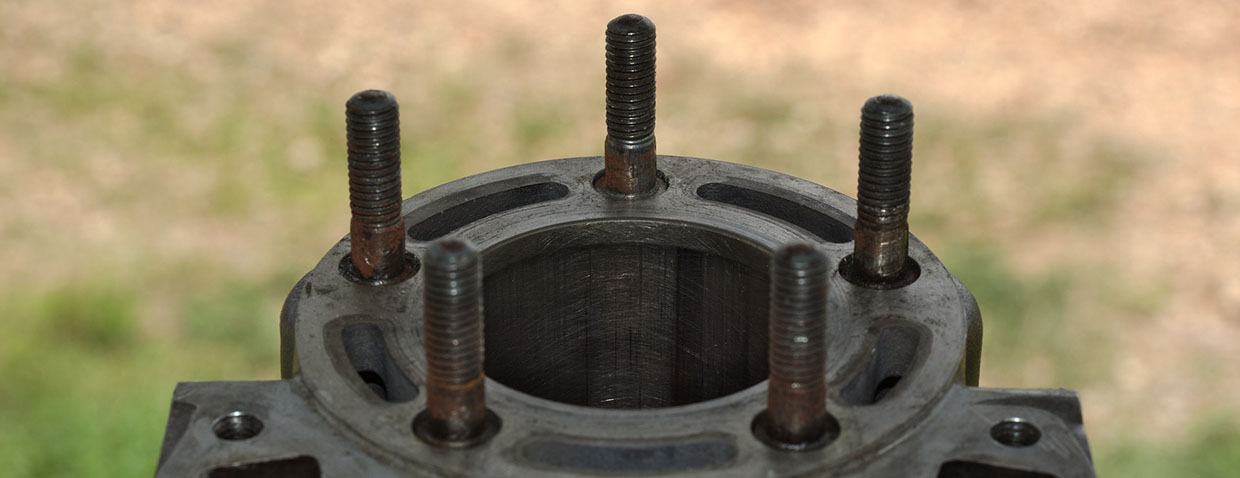

Pictured on the left is the insert you can use if you’ve come across a threaded hole that’s already been repaired with a Helicoil or Time-Sert and the “first time” repair has stripped out. Big-Serts are a thick walled version of Time-Serts. Kits are available with the necessary tools to do a Big-Sert repair in a range of popular thread sizes.

How do Big-Serts work?

Big-Serts work much the same as Time-Serts (see above “How do Time-Serts Work”). However, because the wall of a Big-Sert is much thicker than the wall of a Time-Sert, the insert driver tool cannot force the metal in the bottom threads outwards to lock the insert into the parent hole. To overcome this problem, a socket is cut into the outside of the Big-Sert (see picture at right). This makes the wall of the Big-Sert thinner behind the socket. Then a small metal roll pin is fixed inside the socket. Because the wall is thin enough at the back of the socket to be pushed out by the insert driver tool, the roll pin also gets pushed out and goes into the thread in the parent metal. The roll pin acts as a locking device and stops the Big-Sert rotating and backing out.